| * Kinds of Products & Specifications |

|

|

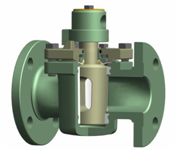

1.TEFLON SLEEVED PLUG VALVES

|

|

MATERLIAL

- BODY / PLUG : ASTM A216 WCB, WCC

: ASTM A351 CF8M, CF3M, CF8, CF3, CN7M, CD4M

: ASTM A352 LCB

- SLEEVE : PTFE, RTFE, TFM 4215

PRESSURE & SIZE RANGE

- ANSI 150LB 1/2¡± ~ 24¡±

- ANSI 300LB 1/2¡± ~ 24¡±

- ANSI 600LB 1/2¡± ~ 12¡±

- JIS 10K, 20K, 40K

- DIN PN10, PN16, PN25, PN40

Main Fluid : Toxic, Flammable, Explosive Fluid Line and No-leakage required Line | |

|

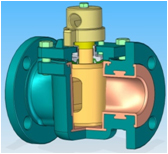

2. TEFLON LINED PLUG VALVES

|

|

MATERLIAL

- BODY / PLUG : ASTM A216 WCB

: ASTM A351 CF8M, CF3M

- LINING MAT'L : FEP, PFA

PRESSURE & SIZE RANGE

- ANSI 150LB 1/2¡± ~ 12¡±

- ANSI 300LB 1/2¡± ~ 12¡±

- JIS 10K, 20K, 40K

- DIN PN10, PN16, PN25, PN40

MAIN FLUID : Acidic or Alkalic Fluid Line specially required for No-Leakage | |

|

|

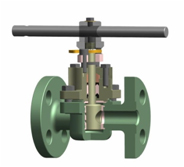

3. EXTENDED PACKING PLUG VALVES

|

|

Feature

Extended triple seal stem packing type. Easy to choose the kinds and material of packing. (Graphite, PTFE V-Packing, VOC packing )

No leaked semi-permanent structure though equally pressured Triple Seal Stem Packing by Gland flange.

Various and steady Leaking Prevention by Steam Sealing.

Able to be used as Live Loaded Extended Packing by using Plate

Spring with an Option to use Gland Flange Bolt to do triple sealing against various temperature effectively.

? Able to prevent stern requirements for leaking prevention and control the requirements for sealing economically. | |

|

|

|

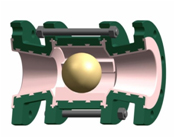

4. TEFLON LINED BALL CHECK VALVES

|

|

Structure

the whole body of the valve has PFA & FEP Teflon linings. RTFE ball Moves freely on the Spacer where lining has been done with Teflon materials and he ball stops in the double sided flange passage way. pressure of the material or the counter flow moves the ball upstream stopping the flow. The spacer of the downstream is in the developing there is a free flow.

Places of use and function

1) Prevent harms done on the pump motor by counter flow

2) Prevent harms done on the pump impeller by the counter flow

3) Interception when the back-head is high

| |

|

|

|

5. JACKETED PLUG VALVES

|

|

1. PA, MNT, DNT, LACTAM, PET POLYMER of the line are used for the accurate control of the temperature of the flow.

2. Applicable for the heating or cooling flow in the Jacket. (MAX. 230¡É~ MIN. -50¡É)

3. Possible supply to valve contacts and Jacket contacts.

4. Complate body anti pressure test before the welding of the Jacket or after the welding for the guarantee of credibility.

PRESSURE & SIZE RANGE

- ANSI 150LB 1/2¡± ~ 24¡±

- ANSI 300LB 1/2¡± ~ 24¡±

- ANSI 600LB 1/2¡± ~ 12¡±

- JIS 10K, 20K, 40K

- DIN PN10, PN16, PN25, PN40

| |

|

|

|

6. TEFLON LINED SWING CHECK VALVES

|

|

Structure

Teflow Lined Swing Check Valve is composed of the Body and 2 Discs all of which comes in contact with the flowing bodies The areas of contact has Teflon mold making the product applicable to places where anticorrosive characteristic is needed instead of high steel alloy valve. The disc with a attached hinge between the valve's body and the flange moves to stop or allow the flow.

Use

1) Prevent of the counter rotation of the Pump Motor

2) Shock prevention of the Pump

3) Shut-off function when the back head is high

Material :

- Body : WCB(316)/PFA,

-Disc : PFA : 4” and Under

WCB/PFA(FEP) : 6” and Under

- Lining Thick: 2.4mm Over | |

|

|

|

7. FULL BORE SLEEVED PLUG VALVES

|

|

MATERLIAL

- BODY / PLUG : ASTM A216 WCB, WCC

: ASTM A351 CF8M, CF3M,

CF8, CF3, CN7M, CD4M

: ASTM A352 LCB

- SLEEVE : PTFE, RTFE, TFM4215

PRESSURE & SIZE RANGE

- ANSI 150LB 1/2¡± ~ 12¡±

- ANSI 300LB 1/2¡± ~ 12¡±

- ANSI 600LB 1/2¡± ~ 6¡±

- JIS 10K, 20K, 40K

- DIN PN10, PN16, PN25, PN40

Main Fluid : Toxic, Flammable, Explosive Fluid Line and No-leakage required Line | |

|